General Electric 805 Restoration Notes

Return to Home

Return to Resources

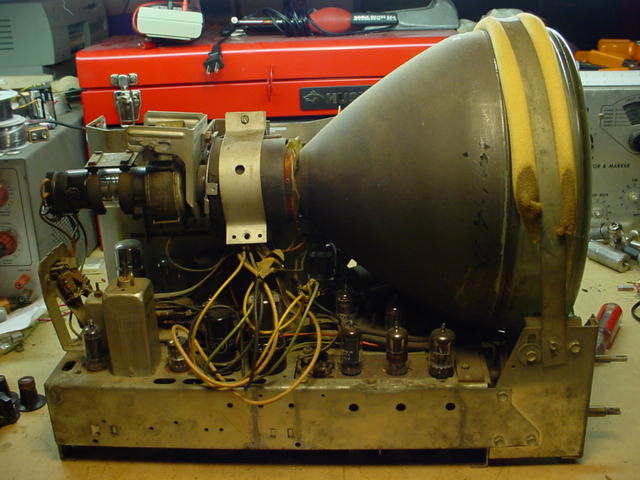

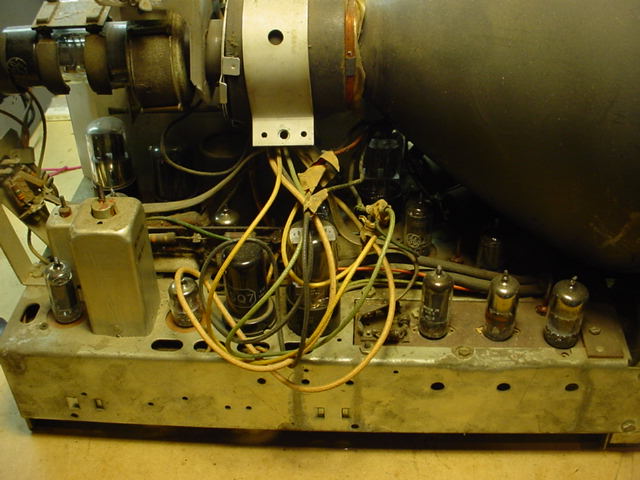

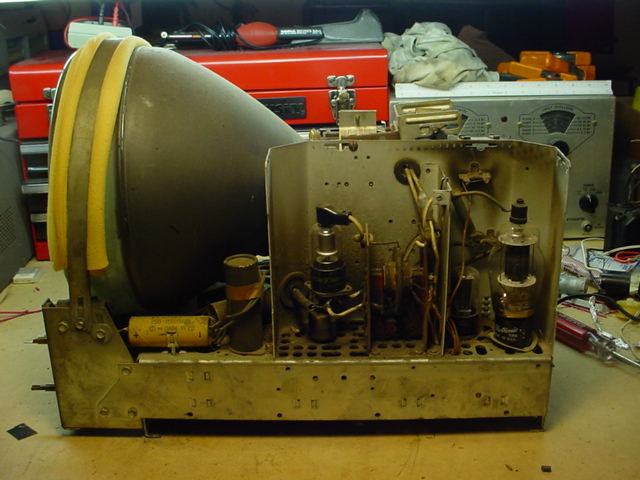

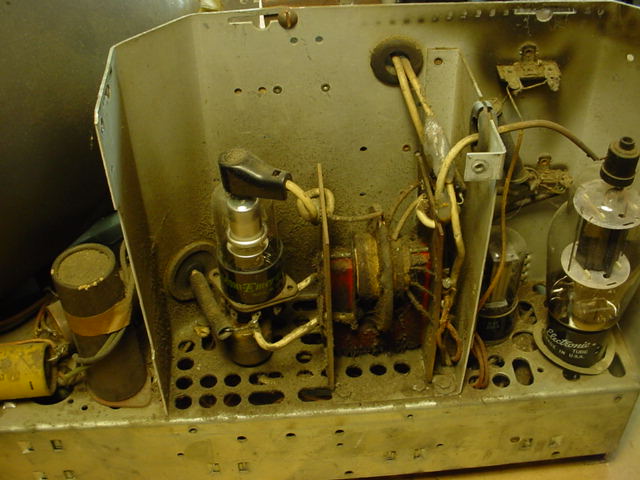

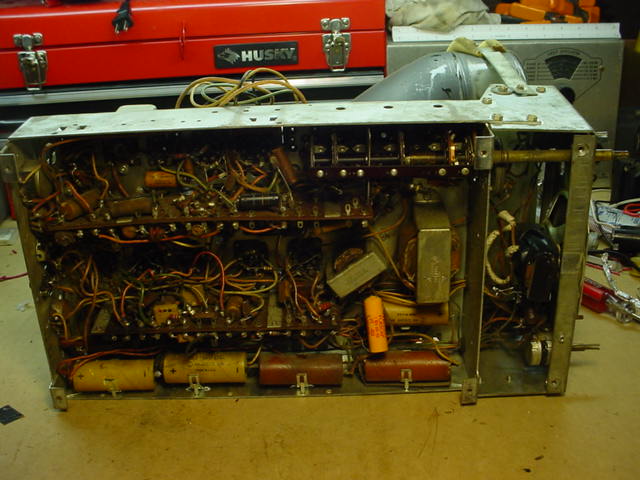

When I first disassembled the television by removing the two front screws and the four bottom screws, I immediately knew this television had been repaired quite often in the past. The second half of the high voltage cage was missing. The deflection yoke was replaced and the new yoke did not fit properly. The 10BP4 CRT also appeared to be a replacement as well. Below is a picture of the innards when I first took the chassis out of the case.

Many of the video amplifier tubes were weak so I replaced most of them with what I had in hand, but nothing was quite good enough to get a picture or snow on the screen. At this point, recapping the entire television was the only necessary option left so I spent several days replacing over 20 capacitors and restuffing those that were visible on the chassis by pushing out the old innards out of the paper body and fitting a new one in place. Finally, some snow came in on several stations, but there was still no picture.

I fiddled with the controls for quite some time until I realized there was a picture coming through but the horizontal frequency was way off. I noticed a variable coil in the rear of the chassis for the horizontal frequency that did not look original and may be off. I ended up adjusting the coil a lot by rotating the screw more than 15 times to bring the horizontal frequency back to where it should be. Once a weak picture came through, rather than the traditional vertical picture flip, the horizontal was flipping badly. The sync separator tube was not functioning properly so I replaced it along with most of the other tubes in the horizontal and vertical circuits. After replacing the tubes and tweaking with most of the controls, the picture became stable.

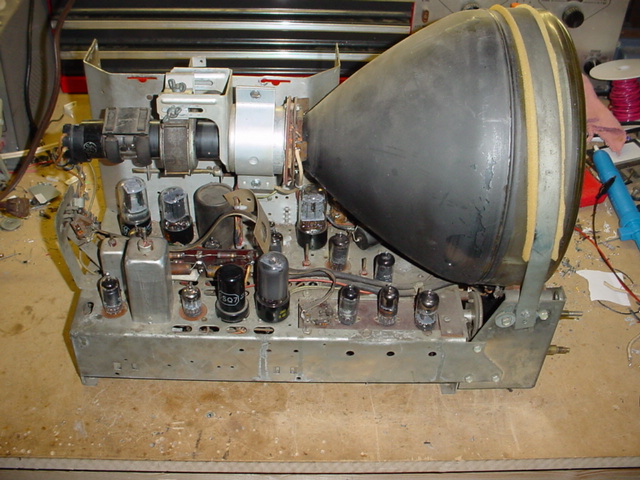

Unfortunately, the picture was still shifted to the left and the vertical size was insufficent to fill the face correctly. One possibility was insufficent high voltage from the flyback, but the picture was quite bright, the B+ voltage was just right, and there was a nice arc from the flyback to a well-insulated screwdriver so this was not the problem. I concluded that the replacement deflection yoke was useless. I fortunately found someone who had a GE 805 parts chassis and was kind enough to sell the original deflection yoke to me for a good price. The positioning problem was immediately resolved after replacing the entire yoke, repositioning the focus coil, and a few control adjustments. Below is a picture of a show with a clear crisp picture.

Back to Top