FSJ Vacuum Routing and Notes

Return to Home

Return to Resources

Return to FSJ Page

In the 1980s, emissions control became a big concern after the 1970s oil crisis and introduction of CAFE standards. The AMC 360 V8 was developed long before emissions control was even a design consideration so attempts to improve emissions on the 360 were pitifully futile. The rated horsepower for a 360 V8 with 2 barrel carburetor in 1970 was 245 HP and virtually the same engine with slightly reduced compression ratio and strangled with emissions control devices dropped to a mediocre 140 HP in the 1980s. Despite the published EPA mileage numbers for 1980s FSJs, most still average 10-12 MPG just like older models with half the power. The vacuum routing for 1980s FSJs had morphed into a complicated spaghetti monster and many of the relevant vacuum related components that fail are hard to replace. There are two thermally controlled valves (Coolant Temperature Overrides or CTOs) on most 1980s AMC 360s for routing vacuum to various places. They all failed and leak internally on my FSJs. Also many previous owners and probably mechanics don't fully understand the vacuum routing diagrams and attempt to make their own tweaks for the better or worse.

Before diving in routing diagrams, it is useful to first understand what the vacuum sources are and what they are used for. Engines will have manifold vacuum and sometimes ported especially on later models. The engine manifold provides full manifold vacuum and that is generally the strongest vacuum that is available across operating conditions. A general rule of thumb for expected vacuum readings on any engine with good compression are listed below. The values are dependent on altitude and generally drop about 1" Hg for every 1000 feet.

- WOT: 0-5" Hg

- Hard acceleration: 5-10" Hg

- Idle or cruising: 15-22" Hg

- Deceleration: 22-28" Hg

On acceleration as the throttle opens up, the vacuum drops because more air is available through the carburetor for the engine to suck so it pulls less from the manifold vacuum port. On deceleration, the engine will be running at a higher RPM when the throttle closes constricting the air flow so the manifold vacuum increases. During steady state cruising speeds, the vacuum is almost about the same as at idle because even though the throttle is more open at cruising than at idle, the engine RPMs are higher and are sucking air at a higher rate so the vacuum level is mostly similar to that at idle. A vacuum gauge can be used to measure the manifold vacuum and also can provide useful insight on any possible engine problems. Readings that are erratic or fluctuating are indicators of vacuum leaks in the hoses or carburetor body, engine compression is weak, or valves are worn.

Manifold vacuum was one method for providing variable ignition timing to optimize the combustion process and maximize engine output power. It is desirable to ignite the fuel-air mixture before TDC (top dead center) early enough to maximize power by ensuring the fuel-air mix is just about to fully combust as the piston reaches TDC so it receives maximum push force without wasted energy, but there is a balance. Too far advanced timing causes preignition, pinging or knocking because the combustion is exerting force against the piston before it reaches TDC and can be damaging. On the other hand, too retarded timing (insufficient advance) means the fuel-air mix is ignited late resulting in wasted combustion energy because the piston is already past TDC and on its way down resulting in a pressure drop so the combustion loses its effectiveness. The end result is poor mileage, sluggish acceleration, or backfiring because the fuel-air mix doesn't completely burn off during the combustion cycle before entering the exhaust cycle. During acceleration, the fuel-air mix will momentarily become very lean because the air flow has increased while the fuel flow hasn't caught up. Momentarily reducing the advance in ignition timing is optimal because the fuel-air mix will ignite much faster as there is less fuel to combust during this brief moment until the RPMs increase. Manifold vacuum provides the signal that can be used to vary the ignition timing because we know the vacuum is lowest on acceleration and highest otherwise so that signal is used to control a spring loaded diaphram in the distributor to adjust the advance and thereby vary the ignition timing.

The ported vacuum option was another type that was introduced mainly for emissions control reasons. The port is just above the throttle plate of the carburator so during idle with the throttle mostly closed, the vacuum is basically 0. As the throttle plate opens and more air flows through the carburetor, the ported vacuum will start increasing and essentially be identical to manifold vacuum as the throttle approaches WOT. So this type of signal could be used to control the EGR (Exhaust Gas Recirculation) to recirculate exhaust gas back into the manifold to reduce engine temperature and emissions when the engine is at cruising speed, but not during idle. Also ported vacuum started being used as the distributor advance signal so the advance behavior was the same as on manifold vacuum except idle would have no advance just like during acceleration. The idea was to reduce emissions by igniting late when idling.

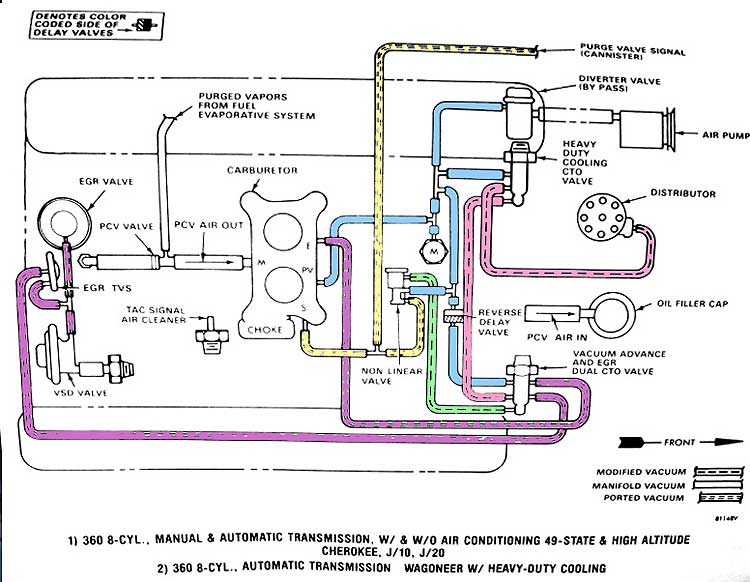

Wait a minute, should ported or manifold vacuum be used for the distributor advance most of the time? Let's take a look at the factory vacuum diagram for a 1982 FSJ. The routings have varied over the decades so you should look up the factory service manual diagram for your particular year. There are some resources online that provide scans of diagrams for several model years. My 1982 factory service manual that I had purchased for the Wagoneer also largely appears accurate for the 1983 J10. Here is a vacuum diagram from the service manual with routes highlighted in color.

Wow, what a messy diagram. Manifold vacuum is highlighted in blue, ported vacuum is the "S" port on the carburetor and highlighted in yellow. A non-linear valve mixes the ported and manifold vacuum and produces a vacuum highlighted in green that is in between ported and manifold during idle. The purple line from the E port of the carburetor is the EGR signal or really just another type of ported vacuum used for enabling EGR when cruising. There are two CTO valves for routing different types of vacuum around depending on engine temperature. When the engine is cold, the EGR is off and the distributor advance highlighted in pink receives the green mixed vacuum. When the engine is at operating temperature, the bottom CTO switches to enable the EGR vacuum control as well as switch the distributor advance (pink line) to full manifold vacuum with a reverse delay valve that seems to me would prevent the distributor from retarding on acceleration resulting in possible preignition issues? If equipped with a heavy duty cooling CTO, when the engine gets too hot then the distributor advance moves to full manifold vacuum like it really should have been in the first place. Full manifold vacuum would have advanced the timing further and result in slightly cooler operation during cruising.

Later 1980s FSJs used ported vacuum instead of manifold vacuum during normal operating temperature. Why the difference? The idea goes back to reducing emissions during idle by igniting late and increasing engine temperature. I personally have tried connecting the distributor advance directly to either ported or manifold. The difference seems negligible during normal operating conditions. But there is some effect on drivability when starting up cold. I noticed preignition issues when using manifold vacuum but that can be reduced by making the fuel-air mix richer with the idle mix screws. I opted to use ported vacuum like the later 1980s FSJs with some timing adjustments for drivability when cold. Remember when the engine is cold, the distributor advance would have received a mixed vacuum that would have slightly advanced the ignition timing beyond the stock 8-10 degrees BTDC during idle because the fuel-air mix is richer due to the choke at start up. I found it best to advance the base timing slightly more to around 14-15 degrees for drivability. Otherwise at 8-10 degrees BTDC, the engine stumbles badly on acceleration until it warms up then it is fine. At 14-15 degrees and ported vacuum directly controlling the distributor advance, the stumbling issue is largely resolved and there is a noticable increase in power on acceleration. Furthermore, starting the engine is easier with the distributor advance on ported because the distributor has no advance and sits at the base BTDC timing when cranking so it's much easier to start without too much advance causing rough clunking noises due to preignition. This solution works great across all seasons of Texas weather, but I can't say how well this works at different altitudes or colder climates. As the saying goes, your mileage may vary.

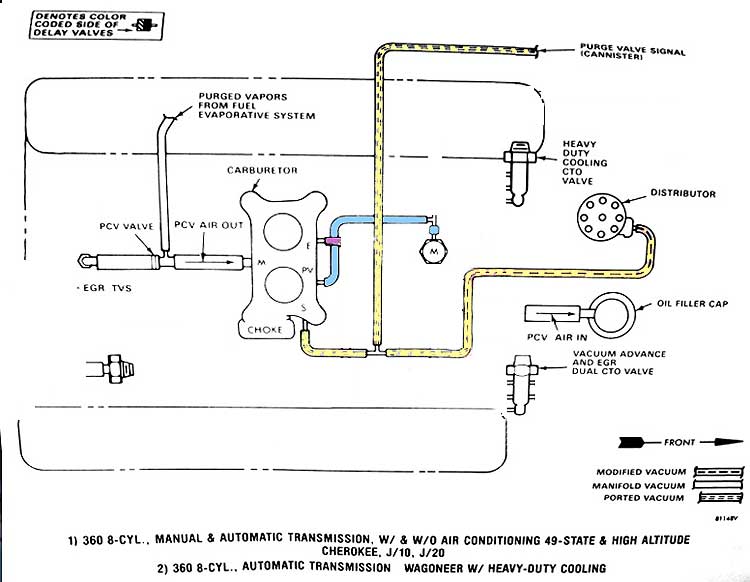

The 1980s FSJ emissions control systems are difficult to maintain because vacuum leaks tend to crop up everywhere and components start failing due to age. The CTOs start leaking internally, hoses start cracking, the charcoal canister purge valve is known to turn into swiss cheese, the EGR valve may start sticking closed or open causing backfiring issues, distributor advance and power valve may not work correctly, and so on. Vacuum leaks cause many drivability problems and rough idling. If your emissions equipment is working then consider yourself fortunate. If you are at the point that drivability issues and maintaining all the vacuum lines are a nightmare, then simplifying things really goes a long way. The EGR and air pump were all removed on my FSJs and Texas law exempts emissions testing for vehicles older than 25 years. It is not like FSJs ever were green friendly anyway emissions controlled or not. Plugs were installed on the exhaust manifold in place of the original air injectors. So without further ado, here is the simplified vacuum diagram that I currently run on my rigs.

Just be sure to cap off the "E" signal for the EGR on the carburetor and all unused manifold vacuum ports. It is also important to verify the purge valve on the charcoal canister that receives the ported vacuum signal holds vacuum! Most charcoal canister purge valves tend to leak vacuum all the time causing rough idle and affecting the distributor advance. Use a handheld vacuum pump to test the purge valve on the canister to make sure it holds vacuum. If it leaks then you don't really need the canister and can tie off the purge valve. However, if you don't want the FSJ to smell gassy in your garage then some creativity will be needed to replace or repair the purge valve diaphram because the whole canister is difficult to replace.

On one final note, the "PV" port on the carburetor stands for Power Valve. This is an important and useful part that helps with drivability on hard acceleration. The power valve port is not a vacuum source but rather is a device that receives manifold vacuum. The power valve works in conjunction with the distributor advance and the accelerator pump by releasing more fuel in the carburetor when the throttle opens up rapidly. The power valve is normally off during idle or cruising because it has full manifold vacuum. Only during acceleration when the manifold vacuum drops will the power valve activate to release more fuel. The power valve that is standard on the Motorcraft 2150 carburetors for the 1980s AMC 360s turns on when the vacuum drops below half of the idle or cruising vacuum level, so usually something like 8-10" Hg. Definitely don't disconnect the power valve or it'll always be on dumping more fuel than necessary and the engine would hesitate or have poor response on hard acceleration.