1940 Buick 51

December 2021 - Engine reinstallation and start up

Return to Home

Return to Resources

Return to Buick 51 page

The exhaust pipes were in good condition and reinstalled. The only real work done was to replace the muffler with a round muffler that looks more period correct, I used a Walker 17854 with 2" diameter inlets. The original mount brackets were cleaned and repainted.

All new 1/4" OD nickel copper brake lines and fittings were installed to replace the crusty old lines.

Newly rebuilt front engine mounts and rear transmission mounts are installed. The rear transmission mounts were rebuilt on exchange at Bob's Automobilia.

One big gamble I took here is assuming that the clutch and transmission did not need any servicing even when the opportunity was present to easily work on them. This would prove to haunt me later.

Engine lowered on frame. The rearmost transmission crossmember was removed for ease of installation to line up the torque tube to the transmission.

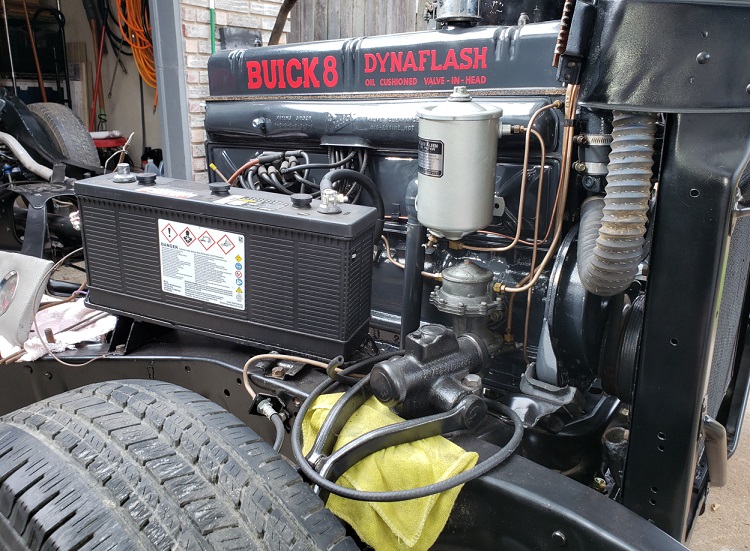

New copper nickel lines were created and installed for the oil and fuel lines. The original mechanical fuel pump was rebuilt using a readily available kit. The pump had not been in use for a long time because the previous owner had been using an electric pump. Also note that the fuel pump is actually a dual pump with a vacuum pump on top used to boost the engine vacuum for the windshield wiper actuators.

Take a look at the crazy 6 volt battery that was originally used. It's long and narrow, and can still be bought today from any automotive parts supply store!

I managed to locate a original generator in working condition as well as a rebuilt Carter WDO carburetor on eBay to install without additional rebuilding effort. I already had the air intake filter from the previous owner that was taken off the car many years ago when the A/C compressor caused fitment issues. Despite living in hot Texas weather, I'm reverting the car back to the original non-A/C configuration.

With jury rigged ignition and starter wiring, I attempted to start the engine again. I had done my best to mark and reinstall the distributor in the same position before it was removed so I would not have to redo the engine timing. Alas, I could not get the engine to start so I went through the procedure to set the engine timing based on the timing mark.

After more unsuccessful starting attempts, I decided to pull the #1 spark plug and the valve cover to observe the values and the piston to find TDC (top dead center). It turns out the flywheel at one time was removed and reinstalled 120 degrees off (6 bolt pattern) and you can see the white mark at the bottom of the flywheel that is supposed to be located at the timing mark window (photo below). Unlike most engines where the timing mark is located on a keyed crankshaft harmonic balancer, 1940 Buicks had the timing mark on the flywheel so it was at risk of being reinstalled incorrectly as was in my case because the flywheel is not keyed to the crankshaft. This also tells me that the clutch was most likely serviced at one time and was encouraging.

The timing mark is supposed to be visible in this little window (annotated with red arrow) just above the starter motor to indicate #1 piston TDC. I reset the distributor based on the actual piston location and managed to get the engine to start right up without trouble.

The radiator did not have any visible signs of damage or leaks so it was cleaned, primed, and repainted using a rattle can spray enamel in satin black.