Large Spark Gap Tesla Coil

Return to Home

Return to Projects

Early version

Specifications:

Primary: 12 turns of 1/4-inch copper tubing, about 1/2-inch spacing, tapped to about 11 turns.

Secondary: 23 AWG magnet wire on 6-inch diameter PVC, 28 inches of winding from bottom to top of pipe.

Spark Gap: 3-segment multiple spark gap, 1-inch copper pipes about 6-inches long

Capacitor: MMC with a string of ten 0.15uF 3kV Cornell Dubilier capacitors bought through Richardson Electronics. Overall capacity is about 0.015uF at 30kV.

Input: 12kV 60mA

Toroid: Aluminium dryer duct

The early version had a 4-inch PVC secondary coil form.

The MMC tank capacitor.

Later version

Specifications

Primary: 17 turns of 0.25" copper tubing, 0.2" spacing.

Secondary: 23-gauge magnet wire 6" diameter PVC, 28 inches from bottom to top of windings.

Spark Gap: Single vacuum ("sucker" gap) spark gap, 1-inch copper pipes about 0.25 inches apart.

Capacitor: One huge 0.01uF 25kV capacitor from Condenser Products Corporation (capacitor was from the 1980s or so)

Input: 12kV 60mA

Toroid: Aluminium dryer duct

The current version with 6-inch PVC secondary coil form.

"Sucker" spark gap

Tank capacitor and transformer

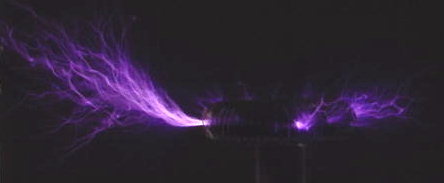

Discharge pictures

4-foot long fluorescent tube atop the toroid

Ion Motor

An ion motor could be created to run off this Tesla coil by using a base made of thick solid wire and the moving part with 22-24AWG magnet wire as shown in the diagram below.

The ion motor in operation.

Back to Top